Stainless steel and aluminum are two of the most popular metals used for manufacturing. Widely used for their versatility and corrosion resistance, aluminum, and stainless steel are staples in the metals industry. To know when it is better to use aluminum vs stainless steel, we must compare factors like their compositions, mechanical properties, and cost.

Aluminum VS Stainless Steel

Main Characteristics of Stainless-Steel vs Aluminum

Stainless Steel

- Contains a minimum of 11% chromium

- Is a ferrous alloy (contains iron)

- Usually magnetic

- High tensile strength

Aluminum

- Non-magnetic

- Low density

- Non-ferrous alloy (doesn’t contain iron)

Aluminum vs Stainless Steel: Which One Do I Use?

Both metals possess properties that are desirable for manufacturing a variety of products. However, the differences in their properties are a key factor when choosing which metal to use.

The Major Advantages of Each Metal

| Aluminum | Stainless Steel |

|---|---|

| -Good Malleability | -High Tensile Strength |

| -High Ductility | -Heat Resistant |

| -Good Conductivity | -Very Durable |

| -Light Weight | -Low Maintenance |

Aluminum vs Stainless Steel: Key Differences

Strength

Stainless steel is heavier and stronger than aluminum. In fact, aluminum is around 1/3 the weight of steel. Even though stainless steel is stronger, aluminum has a much better strength-to-weight ratio than stainless steel.

Conductivity

Steel is a poor conductor of electricity due to its dense protective oxide layer. On the other hand, aluminum is a very good electrical and thermal conductor.

Cost

Aluminum is more costly than stainless steel if you look at the price based on weight. But, if you look at price by volume, Aluminum is more cost-effective because you get more product.

Heat Resistance

When comparing stainless steel vs aluminum, stainless steel has much better resistance to heat with a melting point of 2500 ℉, while aluminum becomes very soft around 400 ℉ with a melting point of 1220 ℉. However, aluminum has the advantage over steel in cold temperatures. As the temperature decreases, the tensile strength of aluminum increases, while steel becomes brittle in low temperatures.

Corrosion Resistance

Aluminum does not rust; however, it does corrode when exposed to salt. Stainless steel is highly corrosion-resistant and does not easily rust. In addition, stainless steel is non-porous which gives it more resistance to corrosion.

Composition

Composition of Major Stainless Steel Alloys

| Alloy Grades | %C | %Mn | %P | %S | %Si | %Cr | %Ni | %Mo |

|---|---|---|---|---|---|---|---|---|

| SS304 | 0.040 | 1.580 | 0.024 | 0.040 | 0.400 | 18.35 | 8.040 | 0.070 |

| SS304L | 0.010 | 1.638 | 0.023 | 0.002 | 0.412 | 18.56 | 8.138 | 0.364 |

| SS316 | 0.080 | 2.000 | 0.045 | 0.030 | 1.000 | 16.80 | 11.20 | 2.500 |

| SS316L | 0.020 | 1.390 | 0.024 | 0.080 | 0.480 | 16.80 | 10.22 | 2.080 |

Composition of Major Aluminum Alloys

| Alloy | %Cu | %Mg | %Mn | %Si | %Zn |

|---|---|---|---|---|---|

| 2024 | 4.4 | 1.5 | 0.6 | 0 | 0 |

| 6061 | 0 | 1 | 0 | 0.6 | 0 |

| 7005 | 0 | 1.4 | 0 | 0 | 4.5 |

| 7075 | 1.6 | 2.5 | 0 | 0 | 5.6 |

| 356.0 | 0 | 0.3 | 0 | 7 | 0 |

Environmental Impact, Recyclability

Stainless steel is known for its good recyclability. According to Napa Recycling, steel is the most recycled material in the world. It has distinct magnetic properties that make it an easy material to recover from the waste stream for recycling. In addition, the properties of steel remain unchanged no matter how many times the steel is recycled.

Even though steel is the most recycled material, aluminum is the most recyclable of all materials. As a matter of fact, discarded aluminum is more valuable than any other material in your recycling bin. Nearly 75% of all aluminum produced in the U.S. is still in use today because aluminum can be recycled over and over again in a true closed loop. To learn more about recycling aluminum, visit the Aluminum Association.

Different Applications of Aluminum vs Steel

Aluminum and steel are everywhere. If you look around at any given place, chances are you will see something containing one of these metals. Below are some common applications of stainless steel and aluminum.

Aluminum Applications

Aluminum is common in the transportation industry because it is lightweight and corrosion resistant

- Automotive

- Train rails

- Airplanes

- Spaceships

- Long-distance power lines

- Window frames

- High-rise buildings (fun fact: the Empire State Building was one of the first structures to contain aluminum)

- Dishwashers

- Washers

- Dryers

- Refrigerators

Stainless Steel Applications

Stainless steel is common in kitchen equipment due to its resistance to corrosion and heat

- Kitchen sinks

- Cutlery

- Food prep tables

- Forceps

- Surgical implants

- Scissors

- Bridges

- Monuments and sculptures

- Buildings

- Auto bodies

- Rail cars

- Engines

Conclusion

When comparing stainless steel vs aluminum, you see they both possess characteristics that make them popular materials for manufacturing. Knowing the differences between them helps you to know when to use aluminum vs stainless steel. For example, aluminum is used for electrical applications because it is conductive and lightweight while stainless steel is not. On the other hand, stainless steel is utilized for things like engines and processing equipment because of its strength, resistance to heat, and corrosion.

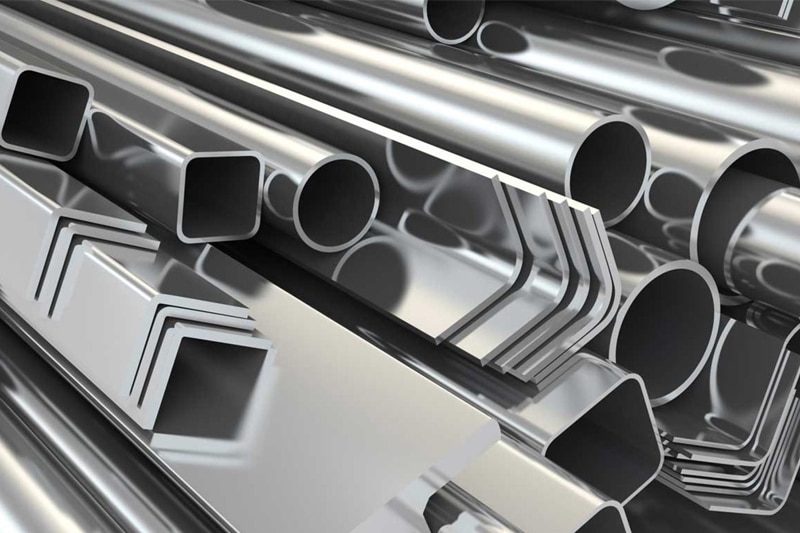

- Stainless Steel Sheet

- Stainless Steel Plate

- Stainless Steel Tube

- Stainless Steel Pipe

- Stainless Steel Bar

- Stainless Steel Rod

- Stainless Steel Coil

- Stainless Steel Strip

- Stainless Steel Angle

- Stainless Steel Flat Bar

- Stainless Steel Channel

- Stainless Steel Wire

- Stainless Steel Wire Mesh

- Stainless Steel Rectangular Tube

- Stainless Steel Cable

- Stainless Steel Threaded Rod

Message

Contact Us

We offer our customers the opportunity to increase profitability by meeting their just-in-time production schedules and offering customized services to meet end-user-specific requirements. Posco Group has always been committed to improving customer service and product quality and providing high-value solutions for customers’ businesses. Satisfying the needs of customers is our daily work goal!